Capabilities

We apply the latest programming and machining techniques to make your parts accurately and on time.

Our in-house core competencies include:

CNC Swiss

The roots of TRAX Automation can be found in the Swiss Department. Our current Swiss department includes 10 machines, varying between 7 and 14 axis capabilities. Machines are equipped with high pressure coolant systems, automatic bar feeders and CNC control. We handle processes such as turning, tapping, threading, drilling, boring, and milling up to 5 axis capabilities. Our programming is done in-house, and always with a keen eye to minimize machine time and produce cost-effective, on-time parts for our customers.

Max Diameter in CNC Swiss is 1 ¼” inch.

CNC Turning

The turning department includes (x3) MIYANO ABX-51TH and a Nakamura TOME WT-150II. All our CNC turning centers have a minimum twin turret/twin spindle, max triple turret/twin spindle.

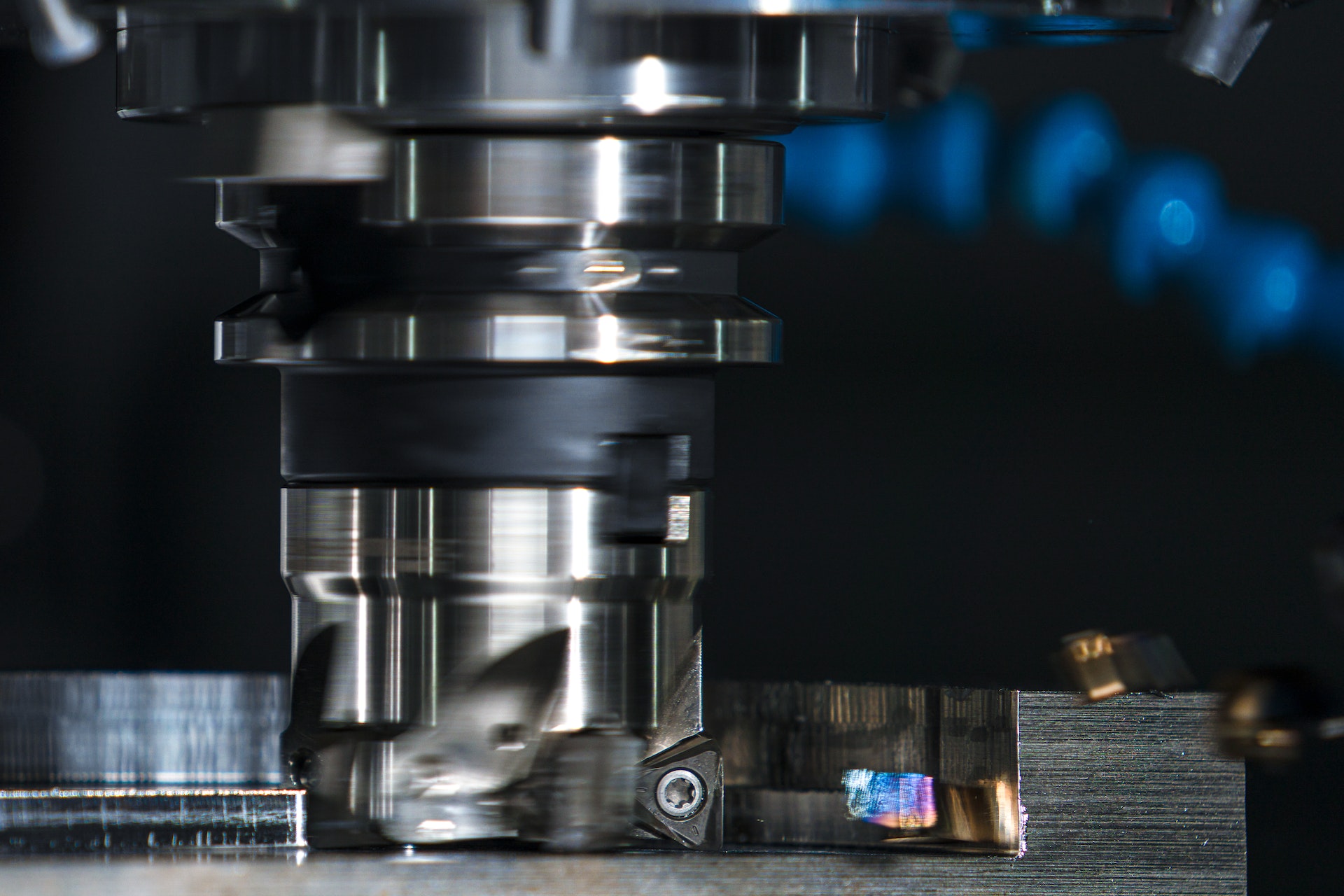

State-of-the-art CNC turning equipment at TRAX enhances the manufacturing process with a high level of automation and precision, delivering quality and consistency. This allows us to minimize machine time and achieve better cost efficiencies for our customers.

Max Diameter in CNC Turning is 2.5”.

CNC Milling

Our milling department consists of 3 Feeler VMP-580 CNC Vertical Mills, equipped with 3 Axis capabilities, as well as twin 4th axis machining capabilities. We are equipped to handle simple drilling and tapping jobs, as well as intricate jobs that require precision knowledge and skill.